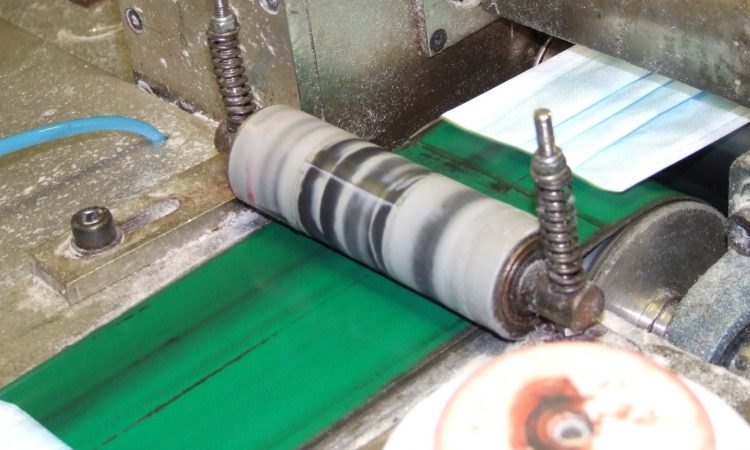

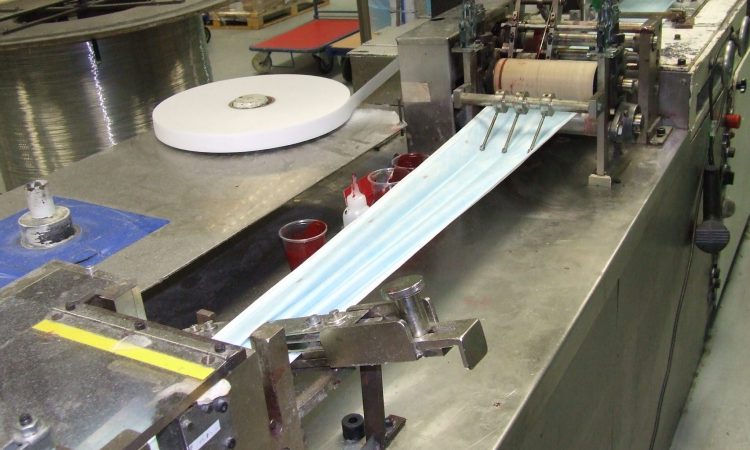

Irema melt-blown process

Melt-blowing is a unique, one-step process in which the melt of a polymer emerging from openings is blown into super-fine fibres by hot, high-velocity air. A molten polymer is blown into ultrafine fibres and collected on a rotary drum or a forming belt with a vacuum underneath the surface to form a nonwoven web.